Transforming Supply Chain Management: What is Touchless Planning?

Intelligent technologies like Decision Intelligence and machine learning support digital transformation, making it easier and less expensive to anticipate consumer behavior.

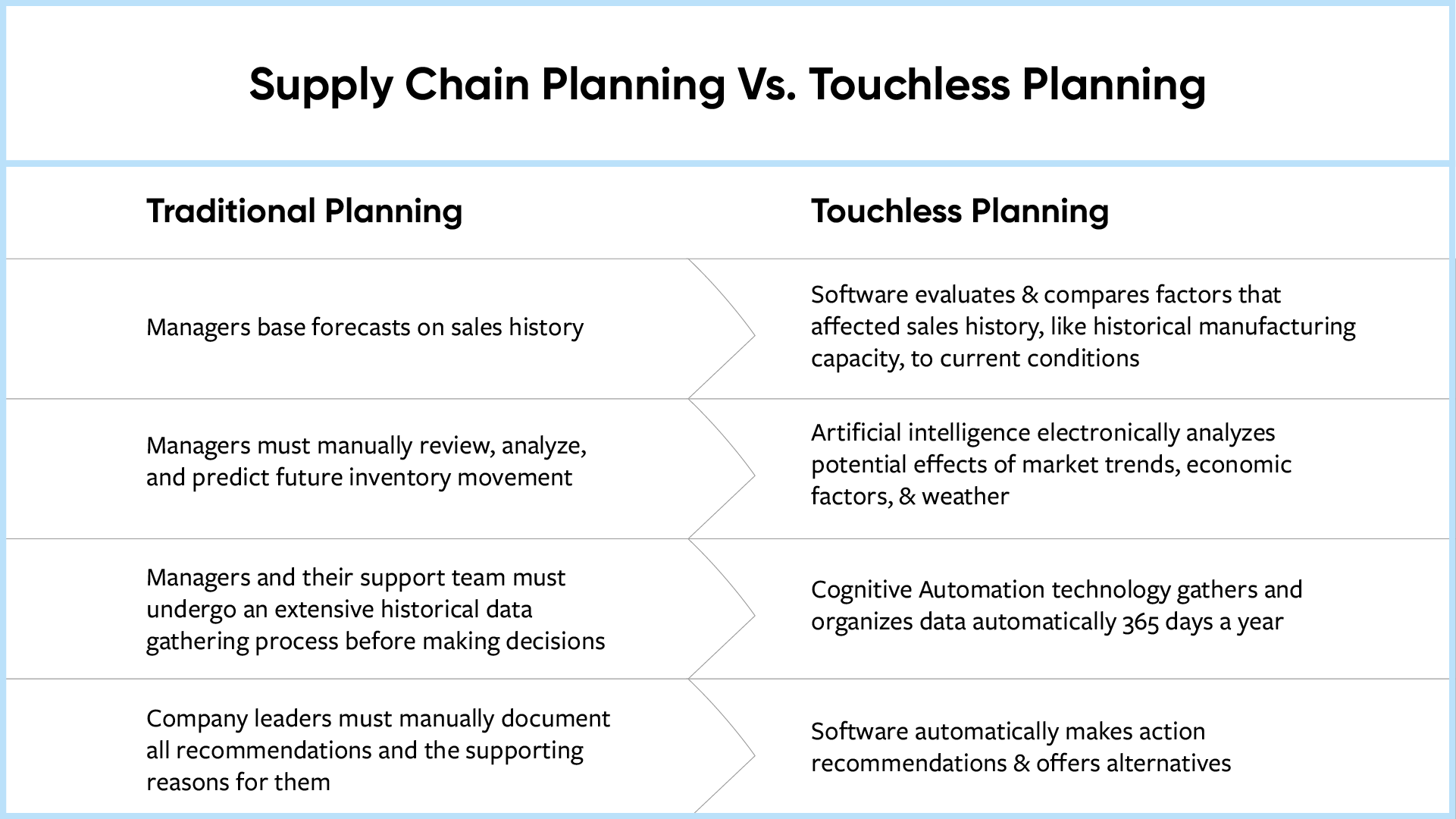

Touchless planning, also referred to as no-touch planning or even touchless demand planning, is an innovative approach that uses artificial intelligence and machine learning to scale an organization’s supply-chain planning process.

The use of this technology allows workers to spend more time analyzing process exceptions and completing other high-order tasks instead of routine work that requires less human brain power, such as gathering and organizing data.

This makes it easier to maximize cash flow, labor resources, and inventory management.

Getting Started with Touchless Planning and Intelligent Automation

To effectively use touchless planning, organizations should first focus on the implementation of a Decision Intelligence platform that syncs and communicates with their existing systems. This type of technology uses crawlers to explore all of the data within a company’s systems and learns how the information interacts and should be organized.

Once it forms a baseline, the technology moves on to managing the data, detecting changes, and forming conclusions on what should happen next. This phase could include making recommendations to hold an order or even increase prices to prepare for forecasted demand changes as a result of an outside force, like politics or weather.

Because professional planners are interacting with the system, deciding which decisions to accept and which to deny, this technology will begin to absorb a similar thought process. This drives how it collects and organizes data in the future and raises decision-making quality overall.

How Machine Learning Supports Continuous Refinement

To understand how Decision Intelligence crawlers work when it comes to touchless planning, compare it to the crawlers Google uses to explore web pages in order to organize and index them later.

For Google to even begin figuring out how to rank search results for different keywords, it has to spend time learning and drawing conclusions about each website’s content and how well it displays a depth of expertise around that particular topic.

It’s an ever-evolving process – think of the constantly-changing algorithms – but the idea is that the system continues to improve search results.

What Organizations Should Adopt Touchless Planning?

Touchless planning is ideal for organizations that rely on supply chain management.

Any businesses that manage inventory, produce goods, or distribute products would benefit. Because of the time and financial investment required to implement touchless planning and Decision Intelligence technology, it’s most suitable for large enterprise organizations or startups planning to scale significantly in a short period of time.

Industries that benefit most from touchless planning are:

- Retailers (including those focused primarily on e-commerce)

- Manufacturers

- Suppliers

Touchless planning and Decision Intelligence technology can transform the way companies work across various industries and allow them to function on a more strategic level instead of taking a reactive stance or “playing small.”

How Touchless Planning and Supply Chain Management Work Together

Although business conditions are changing quickly, there is still a great deal of predictability in the supply chain process. Some customers will continue to order the same mix of products month after month.

In addition, many recession-proof products will likely continue to be in demand. Integrating touchless planning into the supply chain management process helps prevent companies from wasting valuable time assessing these low-risk, highly predictable events.

The system can automate the ordering process and set up annual pricing recommendations for new contracts using data and trends it has access to in the system. This allows more time for evaluating and setting up a plan to deal with disruptive supply chain events.

The ultimate goal of touchless planning is to create time for organizations to apply more strategy and be proactive in their planning approach, using data and Decision Intelligence to drive the future of work.

Get more industry-expert perspectives on supply chain challenges that Decision Intelligence solves – sign up for our “Future Now” webinar series or watch our on-demand sessions today.